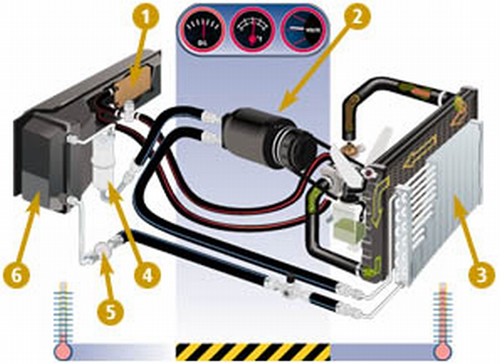

When a system is opened to the environment for repairs, moisture enters the system. The moisture must be removed from the system for the system to operate properly. Moisture in the system will keep a properly charged system from producing the desired cooling effect. If connected, manifold gauges will indicate normal low-side and high-side pressures, but the system will blow warm air; the problem is moisture in the system. A system with air in the system will blow some cold air, but the manifold gauges will indicate abnormally high pressures on both the high and low sides.

When a system is opened to the environment for repairs, moisture enters the system. The moisture must be removed from the system for the system to operate properly. Moisture in the system will keep a properly charged system from producing the desired cooling effect. If connected, manifold gauges will indicate normal low-side and high-side pressures, but the system will blow warm air; the problem is moisture in the system. A system with air in the system will blow some cold air, but the manifold gauges will indicate abnormally high pressures on both the high and low sides.

It is a good idea to evacuate a system even if the system still has refrigerant in it. This extra step could save you from having to do the job twice because there was a leak in the system to begin with. If you pull a 50 micron vacuum and the system holds it, you can rest assure that there are no leaks in the system.

How To Evacuate A System

- Connect the “Yellow” hose on the manifold gauges to the vacuum pump.

- Connect the “Blue” hose on the manifold gauges to the low-side service fitting.

- Close the high-side valve on the manifold gauges and open the low-side valve.

- Start the vacuum pump and let run long enough to pull approximately 30″ Hg.

- Close the low-side valve and shut off the vacuum pump.

- Remove the “Yellow” hose from the pump and cap off.

- Reopen the low-side valve and check the compound gauge reading at interval to see if the vacuum is holding. Any loss in vacuum indicates a leak in the system.